Audio Research has been able to stand in the Hi-End audio industry for 50 years and continues to maintain a high degree of development vitality. It always adheres to the design goal of "High Definition" and uses "purely handmade mass products", so most of the manufacturing processes are the same. One level of handcrafting. In fact, needless to say, they also put special emphasis on the cleanliness of circuit welding during the production process. So they purchased expensive special fertilization agents specifically designed to clean residual impurities after welding. Almost every little thing has an impact on the sound, so they pay great attention to every production detail. Take the circuit board to the cleaning tank and directly use compressed spray to rinse the circuit board. Vacuum tubes have to work continuously for 48 hours, and the long-term tube burning is recorded in detail, and then paired according to the values. Over the years, Audio Research has launched nearly a hundred types of equipment. Due to different circuit designs, the applicable vacuum tube values are also slightly different. Audio Research records and saves all test data, and all qualified vacuum tubes are paired according to their values.

Save HK$21,350

Audio Research

Audio Research I/50 Integrated Amplifier (50th Anniversary Model)

Sale priceHK$49,800

Regular priceHK$71,150

Save HK$41,200

Audio Research

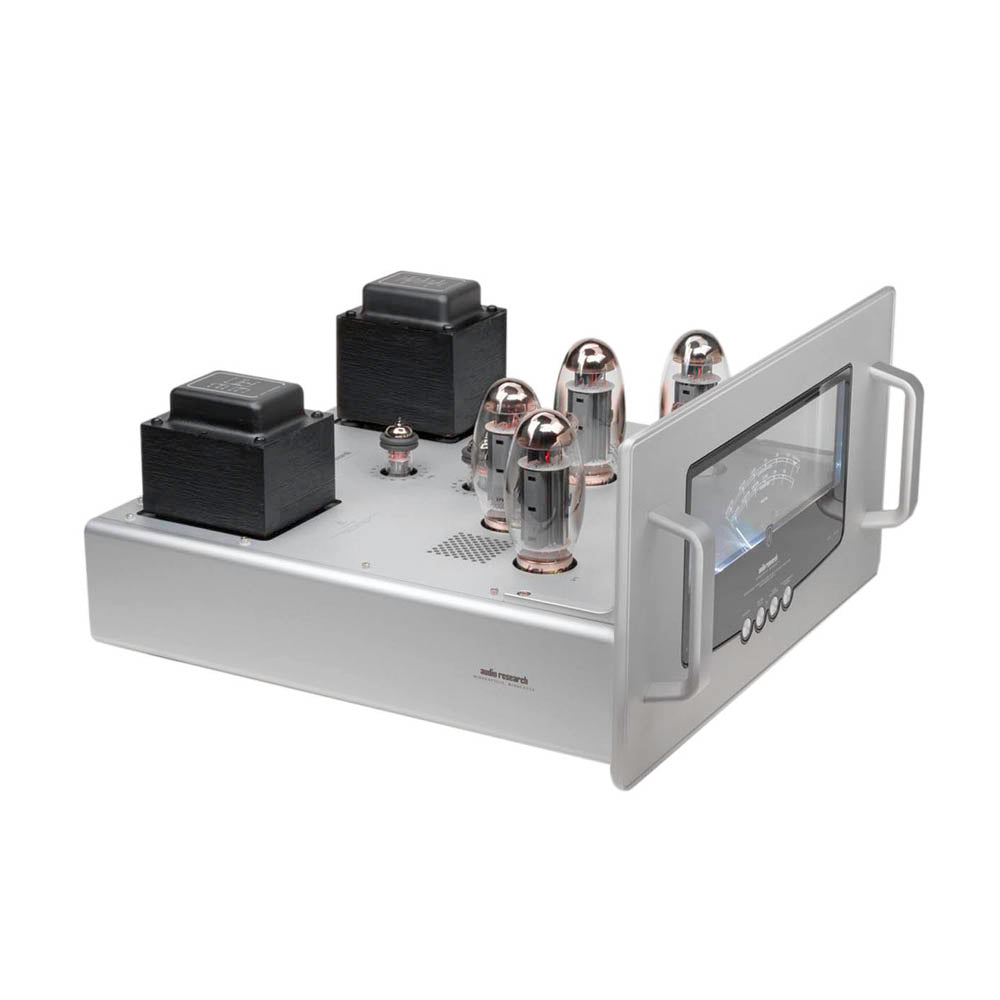

Audio Research VT80 SE stereo power amplifier

Sale priceHK$96,000

Regular priceHK$137,200

Save HK$61,800

Audio Research

Audio Research Reference 80S stereo power amplifier

Sale priceHK$144,000

Regular priceHK$205,800

Save HK$92,600

Audio Research

Audio Research Reference 160S stereo power amplifier

Sale priceHK$216,000

Regular priceHK$308,600

Save HK$147,500

Audio Research

Audio Research Reference 160M MK2 Poweramp Monoblock Power Amplifier

Sale priceHK$344,000

Regular priceHK$491,500